Canon Launches corrPRESS iB17 for Industrial Corrugated Printing

▼ Summary

– Canon announced the corrPRESS iB17, a high-speed digital inkjet press for industrial corrugated packaging production at the FEFCO Technical Seminar 2025.

– The press prints up to 8,000 m² per hour with offset-like quality directly onto corrugated boards up to 1.7 m wide using water-based inks.

– It enables cost-efficient short to medium runs with fast turnaround times, requiring fewer operators and reducing waste by eliminating printing plates.

– The system uses Canon’s proprietary 1200 dpi printheads and water-based inks to achieve vibrant colors and sharp details without a lamination step.

– Designed for indirect food contact, it supports a wide range of board types and sizes, covering approximately 80% of retail packaging applications.

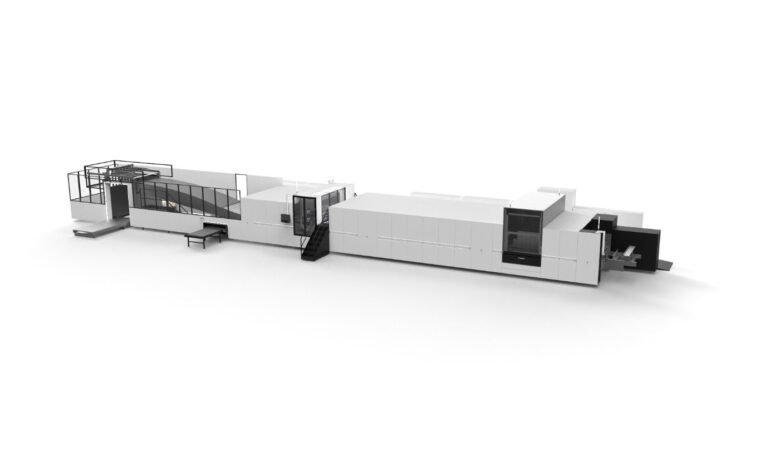

Canon has introduced the Canon corrPRESS iB17, a next-generation industrial inkjet press designed specifically for high-volume corrugated packaging production. Unveiled at the FEFCO Technical Seminar 2025 in Rome, this advanced system achieves printing speeds of up to 8,000 square meters per hour, translating to an annual output of approximately 15 million square meters. It delivers offset-quality results directly onto corrugated boards as wide as 1.7 meters using water-based inks and a primer certified for indirect food contact. The press is engineered to support cost-effective short and medium print runs with rapid turnaround times, requiring fewer operators and simplifying integration into existing production workflows.

This new press responds directly to the growing demands faced by corrugated converters, who increasingly need to manage shorter runs with greater design variation, faster delivery schedules, and premium print quality, all while maintaining cost efficiency. Building upon Canon’s established expertise in commercial digital printing and following a development roadmap previewed at drupa 2024, the corrPRESS iB17 extends the economic advantages of digital printing well beyond traditional short-run applications. It enables cost-efficient production for runs as large as 20,000 square meters, making digital printing a viable option for a broader range of packaging jobs.

A key feature of the corrPRESS iB17 is its high degree of automation, which includes automated printhead cleaning and integrated quality control systems. These functions reduce the need for manual intervention while maximizing operational efficiency. The system also supports sustainable production by eliminating printing plates and associated chemicals, and it generates no contaminated wastewater, unlike many conventional printing technologies. Print-on-demand capability further minimizes material waste, aligning with modern environmental standards.

The press incorporates Canon’s proprietary 1200 dpi piezo printheads along with specially formulated water-based pigment inks and primer. This combination produces an extended color gamut using CMYK, with future support for OVG (Orange, Violet, Green) planned. The system achieves pre-print quality in a post-print process, removing the traditional lamination step while still reproducing vibrant colors, sharp text, and fine details on both coated and uncoated topliners, all at full production speed. An advanced spot primer ensures excellent ink adhesion and consistent color reproduction across various corrugated substrates. The primer and ink are applied in immediate succession without intermediate drying, which helps preserve board integrity and enhances process reliability.

Canon’s integrated drying technology has been fine-tuned to reduce energy use and minimize stress on the corrugated board, further boosting production efficiency. The system accommodates board widths up to 1.7 meters, lengths up to 1.3 meters, and thicknesses from 1 mm to 8 mm, operating at a linear speed of 80 meters per minute. This allows it to serve roughly 80% of retail packaging applications. Because Canon designs and manufactures all core components, including printheads, inks, and drying systems, the company can optimize overall performance more effectively. This end-to-end control results in outstanding productivity, reliability, and print quality tailored for indirect food contact uses.

According to Jennifer Kolloczek, Senior Director of Marketing & Innovation for Production Printing at Canon EMEA, “Corrugated converters are under constant pressure to deliver shorter runs, more customization, and faster turnarounds without sacrificing quality or affordability. The Canon corrPRESS iB17 gives these businesses the agility to meet evolving market needs and unlock new growth opportunities. For Canon, this launch represents a major step forward in our goal to become a leading force in the packaging sector. We are especially pleased that customers in the EMEA region will be the first to experience this innovation. While we are newcomers to corrugated printing, we bring decades of experience in industrial-scale commercial printing and look forward to combining our digital expertise with the deep industry knowledge of converters to advance packaging solutions together.”

For additional details about the Canon corrPRESS iB17, visit the official product page.

(Source: MEA Tech Watch)