Microsoft and IBM Use AI to Revolutionize Battery Tech

▼ Summary

– Microsoft researchers used AI to identify a new battery material (NaxLi3−xYCl6) that could reduce lithium use by 70%, narrowing 32 million candidates to 800 in 80 hours.

– AI models like M3GNet and CDVAE are being trained to rapidly screen millions of material combinations for stability and battery performance, accelerating scientific discovery.

– Researchers globally are developing next-generation batteries with AI to replace lithium-ion designs, aiming for safer, more energy-dense batteries using abundant materials.

– IBM employs AI foundation models to identify high-performance electrolytes and creates digital twins to predict battery degradation, collaborating with an EV manufacturer.

– Quantum computing is seen as the next phase for accurately modeling complex battery systems, addressing limitations of classical computers in simulating materials.

The race to develop superior battery technology is intensifying, with artificial intelligence emerging as a game-changing tool for discovering new materials. In a striking example, Microsoft researchers recently pinpointed a novel substance capable of slashing lithium usage in rechargeable batteries by an impressive seventy percent. This breakthrough began with a staggering thirty-two million potential candidates. Leveraging sophisticated AI models, the team narrowed this down to a single, highly promising material in under eighty hours—a process that traditionally could span many years.

Scientists at the Pacific Northwest National Laboratory are now preparing to synthesize and test this AI-identified material, known as NaxLi3−xYCl6, in an actual battery configuration. The project was initiated to showcase AI’s capacity to solve complex scientific challenges, specifically the search for new battery electrolytes. A superior electrolyte can significantly enhance both safety and performance. Nathan Baker, who leads the project for Microsoft’s Azure Quantum Elements, explained their objective was to demonstrate how AI could dramatically accelerate discovery, sifting through millions of candidates in hours rather than years.

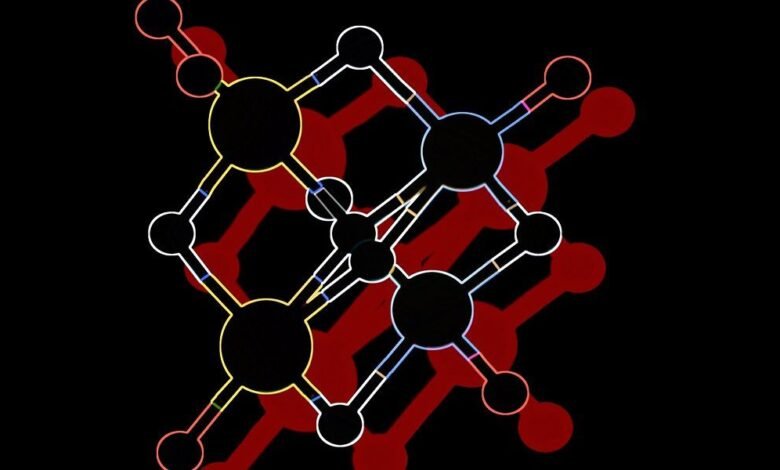

Their model, the M3GNet framework, rapidly simulated molecular dynamics to assess key material properties. The process started by introducing new chemical elements into known natural structures to identify stable molecules, reducing the initial pool from thirty-two million to five hundred thousand. The AI then screened these based on essential battery functions, leaving just eight hundred candidates. Finally, a combination of conventional computing and human expertise selected the final material, which uses significantly less lithium than current commercial batteries.

This effort is part of a global push to create next-generation batteries. Researchers aim to move beyond standard lithium-ion designs, which rely on scarce and expensive elements. The goal is to develop batteries that use more abundant materials, are less prone to fire risks, and can store more energy in a smaller space. AI and machine learning are proving invaluable for navigating the immense data involved in this search.

Dibakar Datta, an associate professor at the New Jersey Institute of Technology, describes the process as “teaching AI how to be a materials scientist.” His team recently used AI to discover five candidate materials for batteries that could outperform lithium-ion. They are focusing on multivalent batteries, which use ions like magnesium or calcium that carry multiple charges. This allows for greater energy storage, though the larger ions present design challenges. Datta’s approach employed a specialized AI model to propose new materials and a large language model to identify the most stable options, ultimately finding five suitable porous materials from millions of possibilities.

Guiding AI through the vast landscape of potential materials is a critical challenge. According to Austin Sendek of Stanford University, the key is balancing speed with accuracy. He emphasizes that successful material discovery requires both depth—profound scientific knowledge—and breadth—the ability to apply that knowledge across an infinite chemical space. This is precisely where AI’s potential shines.

IBM Research is also deeply invested in this AI-driven exploration. Their teams are using chemical foundation models, trained on billions of molecules, to identify new electrolyte formulations. These models learn the fundamental language of chemistry and are then fine-tuned with battery-specific data to predict performance-critical properties. Young-Hye Na, a Principal Research Staff Member at IBM, notes that because their work focuses on novel combinations of existing materials rather than inventing entirely exotic ones, the path to practical application is more direct. IBM is now collaborating with an electric vehicle manufacturer to design high-performance electrolytes for next-generation, high-voltage batteries.

IBM’s application of AI extends beyond material discovery to testing and validation. They are creating digital twins—highly accurate virtual models—of new battery setups. These models allow researchers to predict how a battery chemistry will degrade over its entire lifecycle. Teodoro Laino of IBM Research states that their model, developed with startup Sphere Energy, can forecast long-term battery behavior after modeling just fifty power cycles in the digital environment.

The next frontier in this field is the integration of quantum computing. Both Microsoft and IBM recognize that while current AI is powerful, accurately modeling the extreme complexity of entire battery systems, with all their real-world variables, may require quantum computational power. Baker points out that classical computers struggle with the precise simulation of complex molecules. The future goal is to incorporate quantum computing to generate more accurate data, which will in turn train even more powerful machine learning models for battery innovation.

(Source: Spectrum)