Dutch Startup’s Silicon Anode Tech Challenges China’s Battery Dominance

▼ Summary

– LeydenJar raised €13 million to scale manufacturing of its silicon anode technology for a U.S. consumer electronics company.

– The funding will help build its PlantOne facility in the Netherlands, set to open in 2027, with additional support from the customer.

– Silicon anodes can improve lithium-ion battery energy density by 50% compared to traditional graphite anodes.

– The company uses plasma vapor deposition to create silicon structures that withstand over 450 charge cycles but fall short of automaker targets.

– While targeting consumer electronics first, LeydenJar aims to eventually enter the EV market, though qualification and scaling pose challenges.

A Dutch startup is making waves in the energy storage sector with a fresh infusion of capital aimed at scaling its innovative battery technology. LeydenJar, a Netherlands-based firm specializing in advanced anode materials, has secured €13 million in funding to accelerate production of its pure silicon anode technology. This investment, supported by an additional €10 million commitment from a major U.S. consumer electronics company, will help establish the company’s first manufacturing facility, PlantOne, in Eindhoven by 2027.

Currently, the global supply chain for lithium-ion batteries remains heavily dependent on China, particularly for graphite anodes. Silicon anodes represent a promising alternative that could reshape this dynamic while delivering significant performance improvements. Although energy density in conventional batteries has doubled over the last ten years, LeydenJar claims its silicon-based anodes can boost energy density by 50% compared to traditional graphite.

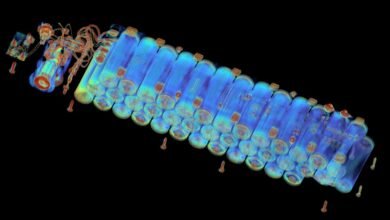

Battery makers have long recognized silicon’s potential but struggled with its physical limitations. Pure silicon tends to expand considerably when storing lithium ions, leading to structural breakdown over repeated charging cycles. To overcome this, companies like LeydenJar have developed supportive frameworks. The firm uses a plasma vapor deposition process to grow porous silicon columns on a copper substrate. This design allows the material to swell and contract without fracturing, maintaining integrity through hundreds of cycles.

The technology promises not only greater energy storage but also faster charging times and a reduced carbon footprint. LeydenJar’s anodes can endure more than 450 full charge cycles before dropping below 80% capacity. While this demonstrates meaningful progress, it still falls short of the 1,000-cycle threshold typically required by electric vehicle manufacturers.

For now, LeydenJar is focusing on the consumer electronics market, a strategic entry point also adopted by competitors like Sila. Breaking into the automotive industry presents steeper challenges, including lengthy validation processes and the need for massive production scaling. Still, the battery sector remains highly dynamic, and a technology offering substantial gains in performance without compromising durability could attract significant interest from automakers and electronics giants alike.

(Source: TechCrunch)