Varda’s Space Manufacturing Breakthrough: The Next Step is Routine

▼ Summary

– Varda CEO Will Bruey predicts specialized spacecraft will deliver pharmaceuticals from orbit within 10 years and space travel will be cheaper than Earth living for working-class humans in 15-20 years.

– Varda has successfully manufactured and returned ritonavir crystals from orbit using small capsules launched on SpaceX missions, proving commercial in-space pharmaceutical production.

– Microgravity enables precise control over crystallization, producing drugs with better stability, purity, and shelf life by eliminating Earth’s interfering forces like sedimentation.

– Varda’s business model relies on repeated launches for drug manufacturing, creating scalable demand that could drive down launch costs and benefit other industries.

– The company overcame regulatory hurdles for its first capsule return and now holds an FAA license for regular U.S. reentries while expanding into hypersonic testing for defense applications.

The future of pharmaceutical manufacturing may not be on Earth at all, but in the quiet vacuum of space. Varda Space Industries is pioneering a new approach by producing drug crystals in orbit, leveraging microgravity to achieve purities and structures impossible under terrestrial conditions. CEO Will Bruey envisions a near future where specialized spacecraft regularly streak through the night sky, returning to Earth with precious pharmaceutical cargo manufactured beyond our atmosphere.

Bruey’s confidence stems from his experience watching ambitious projections become reality during his engineering tenure at SpaceX. He recalls working on the third Falcon 9 flight, a vehicle that has since completed hundreds of missions. What once seemed like distant science fiction, reusable rockets achieving airline-like frequency, now feels attainable within similar timeframes. This perspective shapes his belief that space-based manufacturing will follow a comparable trajectory from novelty to routine operation.

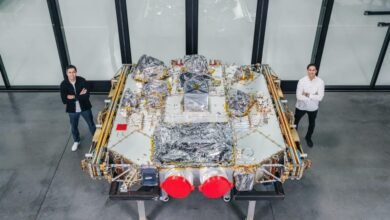

Varda has already demonstrated the core capability, becoming just the third corporate entity to successfully return material from orbit. Their February 2024 mission brought back ritonavir crystals, an HIV medication, joining the exclusive ranks of SpaceX and Boeing. The company accomplishes this using its W-1 capsule, a compact conical spacecraft roughly the size of a large kitchen trash can. These capsules hitch rides on SpaceX missions and are supported in orbit by Rocket Lab’s spacecraft bus, which provides essential power, communications and control systems.

The fundamental advantage of space manufacturing lies in microgravity’s elimination of sedimentation and convective flows that disrupt crystal formation on Earth. Without these interfering forces, Varda achieves unprecedented control over the crystallization process. This enables creation of uniform crystal sizes and novel polymorphs, different structural arrangements of the same molecule, that can significantly improve drug stability, purity and shelf life.

Though pharmaceutical manufacturing in orbit requires weeks or months, the return process is remarkably swift. Completed capsules detach and reenter Earth’s atmosphere at staggering speeds exceeding Mach 25, protected by advanced heat shields before parachuting to soft landings.

Bruey emphasizes that Varda operates not in the space industry but in what he calls the “in-space industry,” treating orbital environments as simply another manufacturing location. He compares their approach to having a special oven with an additional “gravity knob” that enables formulations otherwise impossible to create.

The company focuses not on discovering new drugs but on improving existing medications through superior crystallization techniques. This builds upon years of pharmaceutical research conducted aboard the International Space Station by established companies like Bristol Myers Squibb and Merck. Varda’s innovation lies in commercializing this process through dedicated infrastructure designed for repeated, reliable operation at pharmaceutical industry scales.

Two critical developments make this endeavor timely. First, space launches have become bookable and predictable, transforming from chartered flights to scheduled services. Second, companies like Rocket Lab now produce satellite buses available for purchase, dramatically simplifying orbital operations.

Currently, only high-value pharmaceuticals justify the transportation costs, but Bruey outlines what he terms the “seven domino theory” to explain how this will evolve. Reusable rockets represent the first domino, followed by manufacturing and returning drugs from orbit. The crucial third domino involves getting a space-manufactured drug into clinical trials, establishing what Bruey calls “perpetual launch” requirements.

This creates a fundamentally different business model from traditional space companies. Where satellite operators treat launches as capital investments to establish constellations, Varda’s model generates ongoing launch demand, each drug formulation requires manufacturing runs, which in turn require launches. This creates scalable, predictable demand that could ultimately drive down launch costs for everyone.

The path nearly ended before properly beginning when Varda’s first capsule remained stranded in orbit for six months due to regulatory hurdles. The Utah Test and Training Range, primarily focused on military operations, repeatedly bumped Varda’s landing windows. Each rescheduling invalidated their reentry license, forcing the company to restart the approval process.

Bruey recalls the tension as eighty employees watched their two-and-a-half-year project orbit Earth with uncertain return prospects. The breakthrough came in February 2024 when W-1 finally landed, becoming the first commercial spacecraft to touch down on a military test range under the FAA’s Part 450 licensing framework.

This regulatory perseverance yielded unexpected benefits. Varda now operates landing sites in both the U.S. and Australia and has developed a secondary business in hypersonic testing. Their capsules naturally create extreme reentry conditions, reaching Mach 25 with plasma formation, that are prohibitively expensive to replicate in ground facilities. The Air Force Research Laboratory has already flown experiments aboard Varda capsules, testing materials and sensors in actual flight conditions.

Investor enthusiasm reflects this potential, with the company raising $329 million in its most recent funding round. Resources are directed toward expanding their El Segundo pharmaceutical laboratory and hiring specialists to tackle more complex molecules, eventually including biologics like monoclonal antibodies.

While significant challenges remain before space-manufactured drugs reach pharmacy shelves, Bruey maintains that the timeline for this transformation is shorter than most anticipate. The convergence of reliable launch services, available spacecraft components, and regulatory progress creates conditions for rapid advancement in orbital manufacturing, potentially revolutionizing how we produce essential medicines while opening space to broader industrial use.

(Source: TechCrunch)